Press Fittings: How they are changing HVAC installations

Installing copper fittings can be a tricky process:

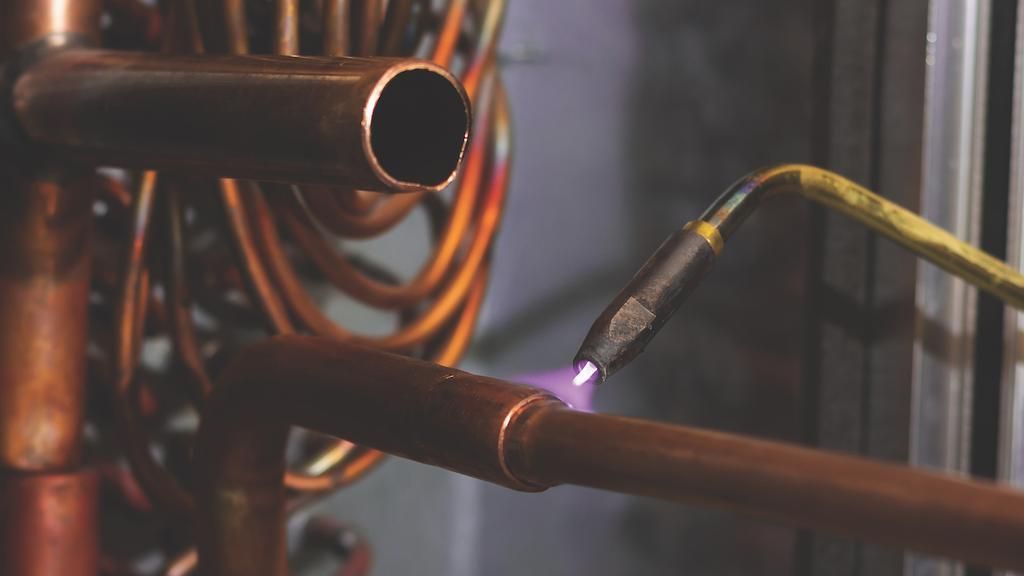

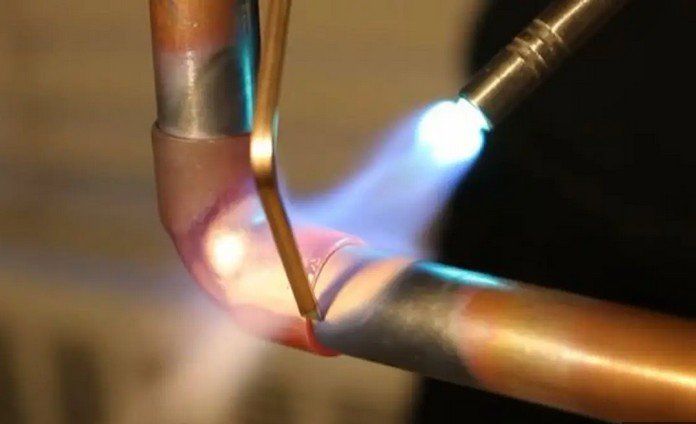

For decades, HVAC contractors have used “brazing” as their method of adding in copper linesets and fittings to tie the HVAC system together. This practice involves using a material called “Sil-Fos” made of copper, aluminum, and phosphorus to melt and join with the copper lineset or fittings. When it dries, it creates a leak-free joint that traps the refrigerant inside the HVAC system.

So, what all is involved in brazing in a copper joint and why have contractors started adopting a new method of practice? Traditional brazing requires an HVAC contractor to carry the tools necessary to perform the braze, involving a torch kit, oxygene, acetylene and nitrogen gases. Oxygen and acetylene are sparked into a flame and used to melt the Sil-Fos to the copper lineset or fitting, while nitrogen is used to purge the line. Purging the line prevents oxidation, a chemical reaction that results from oxygen combining with copper to form copper oxide. Nitrogen prevents oxidation from occurring by displacing the oxygen in the line.

Brazing can be a tricky process to perform at a high level because it requires proper safety measures, cleaning, materials, heat control, and testing for leaks. An inexperienced contractor may find it difficult to perform a successful braze joint, especially in situations or spaces where it is difficult to work on HVAC systems. In some cases, brazing requires work permits for open flames to perform the action. All these can be potential deterrents to brazing and provide reasons as to why HVAC contractors are opting for a new solution to joining copper fittings and linesets – press fittings.

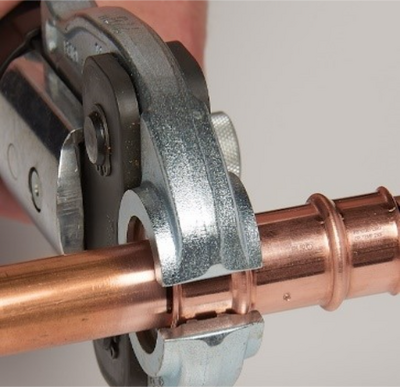

HVAC manufacturers have adapted and created a new solution to brazing with the creation of press fittings, a fitting that does not require brazing for a leak-free connection. The process involves pressing, or compressing, a fitting onto the copper line with the use of a specialized hydraulic tool. Although the initial investment in tooling is higher, many HVAC contractors are electing to switch their practices to using press fittings for many benefits, such as, ease of use, reduced safety risk, and faster installation.

How do press fittings work?

Ensuring the correct size fitting is a crucial first step in the process. With sizes ranging from ½” in diameter to 4”, there are plenty of options to choose from depending on the application a contractor is working on. Not only does the size apply to the fitting itself, it also applies to “jaw” used in the press tool. The jaw is responsible for clamping onto the fitting when compressed by the press tool.

Once a contractor has selected the proper size fitting and jaw, the next step is to deburr the end of the copper tube to remove any rough edges. This helps create a smooth surface for the fitting to attach to. After the tube has been deburred, the contractor will slide the fitting over the tube to the appropriate insertion mark. This ensures the O-ring within the fitting is properly seated on the tube. The last step is to lock the jaw on the fitting and use the press tool to compress the fitting, creating a leak-free joint.

Across the country HVAC contractors are finding that although press fitting applications requires a higher initial investment, the benefits outweigh the costs in many scenarios. They are able to install copper fittings and linesets at a safer and faster rate, leading to greater operational efficiencies.